Wide Product Range

Offering a comprehensive selection of thermoplastics suitable for various applications.

Trusted Partnerships

Building lasting relationships with clients based on reliability and trust.

Advanced Manufacturing Capabilities

Equipped with state-of-the-art facilities to produce precision-engineered plastics.

Featured Products

Our Distribution Partner

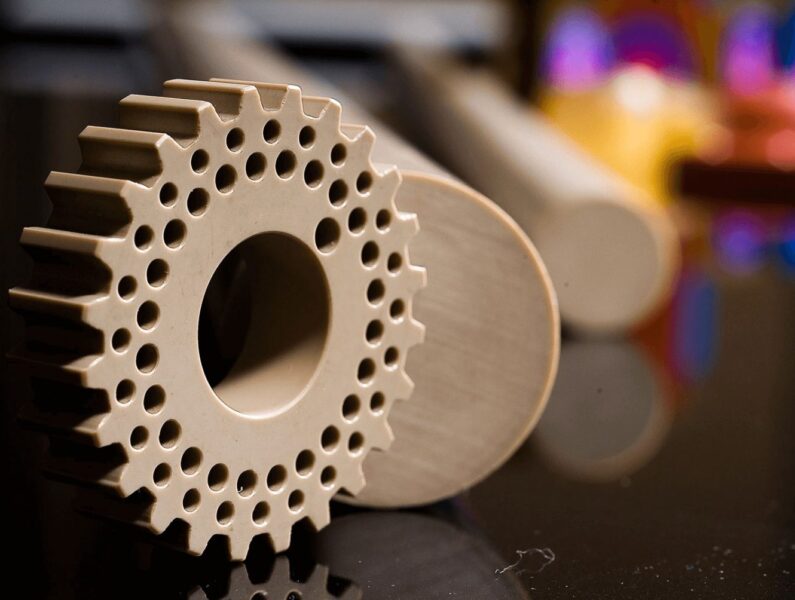

Acetal (POM)

Acetal (POM-C) is a semi-crystalline thermoplastic with good dimensional stability and frictional properties. It contains high mechanical strength, toughness and provides an ease of machining not present in other plastics. Acetal is primarily for customers in which precision componentry with small tolerances are of importance. In contrast to Nylon, Acetal provides very low moisture absorption, making it a necessity for applications within a submerged or wet environment. This is due to its ability for mechanical properties to be maintained through wet or harsh environments. Chemically resistant, Acetal is also a great choice for corrosive conditions. With our workshop in Sydney, B Plastic is able to machine components efficiently and with minimal tolerances.

Custom Moulded Polyurethane Components

We’re here to either produce your current product or assist in the development of a new one. Our team is well-equipped to collaborate with you starting from the design phase, moving through prototyping and into full-scale production. Once we have a solid grasp of your unique requirements, we can recommend optimal materials and the most economical manufacturing processes at your disposal.

If you’ve got a particular product design or a vision in mind, we’re excited to work on making it a reality. Feel free to reach out to us for any custom polyurethane moulding you require.

HDPE (High Density Polyethylene)

Nylon (PA)

Nylon PA is produced through two methods, cast and extrusion. Cast nylon demonstrates higher molecular weight, higher crystallization then extruded Nylon. Typically, Nylon is known for high mechanical strength, good wear resistance, sliding function and great machinability. In contrast to polyethylene products, Nylon absorbs moisture and is prone to expansion, as a result, it is not recommended for wet environments. Each grade of Nylon is manufactured to have different characteristics such as self lubrication, wax filled, UV – resistance and more. With our workshop in Sydney, B Plastics is able to machine components efficiently and with minimal tolerances.

Nylon Grades Available Include: Natural, Moly, Blue, Green, T-Glide, Aquanyl & Impact Resistant.

See Below For More Information.

PEEK (Polyetheretherketone)

PEEK material (polyetheretherketone) is a high-performance semi-crystalline engineering thermoplastic with outstanding harsh chemical resistance, very low moisture intake, good fire performance, excellent mechanical strength across a broad temperature range, and good dimensional stability. PEEK plastic is tough, strong, and rigid, with superior creep resistance, and is excellent for applications where thermal, chemical, and combustion properties are critical to performance. PEEK material retains its stiffness and strength for use in harsh high-pressure and high-temperature (HPHT) environments. PEEK is often used as the body for electrical connectors to minimize thermal expansion, provide chemical resistance, and to promote effective sealing. PEEK materials for a variety of sealing system components, as well as sensor housings and numerous high-performance applications in aircraft engines and other demanding environments. With our workshop in Sydney, B Plastics is able to machine components efficiently and with minimal tolerances.

Polyester (PET)

SAFEGUARD UV2™ Polycarbonate (PC)

Polycarbonate (PC) is a transparent, amorphous thermoplastic, offering excellent impact strength and high dimensional stability. A premium grade of plastic, polycarbonate has a high resistance to corrosive environments, excellent electrical stability and impact resistance. Outdoor applications are a particularly strong application for PC due to being lightweight and possessing great UV resistance. With our workshop in Sydney, B Plastic is able to machine components efficiently and with minimal tolerances.

Sheet, Rod & Tube

Polyurethane is a versatile polymer renowned for its durability, flexibility, and resistance to abrasion, making it a sought-after material across various industries. B Plastics, a leading supplier in polymer solutions, offers a comprehensive range of sheet, rod, and tube in a variety of sizes. These polyurethane stock shapes cater to diverse applications, from engineering to manufacturing, providing superior performance and reliability in select applications. With B Plastics commitment to quality and precision, customers can trust in the consistency and integrity of their polyurethane material, ensuring optimal results for their projects.

Teflon (PTFE)

The properties of PTFE (Polytetrafluoroethylene) derive from its chemical structure, consisting of a bond of carbon and fluorine. PTFE is also known as an almost universal chemical resistance. The low co-efficient of friction as well as minimal abrasion wear create an excellent material for sliding applications. Additionally, PTFE will operate consistently within harsh UV and extreme heat environments, including temperatures up to 260°C. PTFE also has excellent electrical properties, allowing use within high voltage applications. PTFE is a physiologically inert material. Physiologically Inert materials are too dense to absorb bacteria or liquid, preventing it from expanding or contracting. As a result, PTFE is excellent for applications within the food or beverage industry.

With our workshop in Sydney, B Plastic is able to machine components efficiently and with minimal tolerances.

Ultra High Molecular Weight Polyethylene (UHMWPE)

In the same polyethylene family as HDPE, Ultra-High Molecular Weight Polyethylene (UHMWPE) is dense, strong and abrasion-resistant. It’s especially well suited for holding up against wear from constant friction between moving parts. UHMWPE is fairly low cost and can be used for a wide variety of applications. Though it can be fabricated and machined, it’s not as well suited to forming specific shapes as HDPE. However, it is generally able to hold up better against friction and wear over time. Relevant for food related applications, UHMWPE is compliant with FDA/BfA requirements and is physiologically inert.

With our workshop in Sydney, B Plastic is able to machine components efficiently and with minimal tolerances.

High-Performance Materials

Engineered with precision, our thermoplastics ensure high performance under extreme conditions, making them ideal for demanding applications.

L Profile

₹99.00Balance Weave Belt

₹99.00SP-CC600

₹99.00Bun Moulding Plates

SP-880 TAB SERIES

₹99.00SP-802 SERIES

₹99.00Roller Chain Guide

₹99.00UCFL – Two Holes Unit

₹99.00SP – 2120

₹99.00SALE PRODUCTS

Acetal (POM)

Acetal (POM-C) is a semi-crystalline thermoplastic with good dimensional stability and frictional properties. It contains high mechanical strength, toughness and provides an ease of machining not present in other plastics. Acetal is primarily for customers in which precision componentry with small tolerances are of importance. In contrast to Nylon, Acetal provides very low moisture absorption, making it a necessity for applications within a submerged or wet environment. This is due to its ability for mechanical properties to be maintained through wet or harsh environments. Chemically resistant, Acetal is also a great choice for corrosive conditions. With our workshop in Sydney, B Plastic is able to machine components efficiently and with minimal tolerances.

Agricultural Industry Applications

Alkaline Tank

Balance Weave Belt

Wire mesh belts are used in extremely high temperatures (baking, bakery, and snack food conveying) or sub-zero temperature (frozen food conveying) applications. We provide wire mesh belt conveyors which are appropriate for the application. Closed wire mesh belts allow flexibility for conveying little components. We offer two models with a variety of wire mesh configurations. We use three different bed materials-UHMWPE plastic, roller or wears strip slider.

Balanced Compound Belt

Wire mesh belts are used in extremely high temperatures (baking, bakery, and snack food conveying) or sub-zero temperature (frozen food conveying) applications. We provide wire mesh belt conveyors which are appropriate for the application. Closed wire mesh belts allow flexibility for conveying little components. We offer two models with a variety of wire mesh configurations. We use three different bed materials-UHMWPE plastic, roller or wears strip slider.

Can Invertor

Bun Moulding Plates

Engineering Applications

Transport Industry Applications

Packaging Applications

Mining Industry Applications

Shaping Tomorrow with Reliable Plastics Today

At B Plastics, we believe in crafting solutions that stand the test of time. With a focus on reliability, innovation, and sustainability,

Crate Chain – 1702

Polyester (PET)

Tooth Belt Guide

We manufacture all types of Tooth Belt Guide. They are available in several grades of UHMW plastic. UHMWPE chain guides extend chain life, decrease noise and friction. Chain guide material used for conveyor side guide and conveyor frame support provided in ultra-low friction ULF material and highly self-lubricating.

Side Brackets and Guides

We manufacture Side Brackets and Guides B plastics is one of the most trusted manufacturers and suppliers of high-quality conveyor components.We are a one stop solution for all the conveyor component needs for OEMs, End users, Machine builders and system integrators. Our conveyor components range from leg pads, frame supports, side guides, side brackets, bearing blocks, transfer rollers etc.,

Flat Brushes

We manufacture a wide range of brushes for industrial applications that are made from a variety of brittle materials. B Plastics offers a customized range of industrial brushes for specific cleaning applications. We cater to a wide range of industries including the packaging industry, food processing, dairy industry, steel plant and much more.

Center Profile

UHMWPE Wear strips are used to support and guide roller chains, product and conveyor belts, which provides high wear resistance and a low coefficient of friction. They are designed to prevent chain or belt movement and cut back vibration which may increase bearing and motor loads. Wear bends also can be provided usually used to guide conveyor belts around corner tracks.

B Plastics is the largest and most trusted manufacturer of wear strips. The UHMWPE wear strip is manufactured using materials consisting of a low coefficient of friction thus enabling smooth and continuous product transit, thus highly preventing the belt movement and increasing chain life.

Clip On Profile

UHMWPE Wear strips are used to support and guide roller chains, product and conveyor belts, which provides high wear resistance and a low coefficient of friction. They are designed to prevent chain or belt movement and cut back vibration which may increase bearing and motor loads. Wear bends also can be provided usually used to guide conveyor belts around corner tracks.

B Plastics is the largest and most trusted manufacturer of wear strips. The UHMWPE wear strip is manufactured using materials consisting of a low coefficient of friction thus enabling smooth and continuous product transit, thus highly preventing the belt movement and increasing chain life.

SP-880 TAB SERIES

High Quality Materials

At B Plastics, we specialize in delivering high-quality, innovative plastic solutions that cater to a wide range of industries and applications.