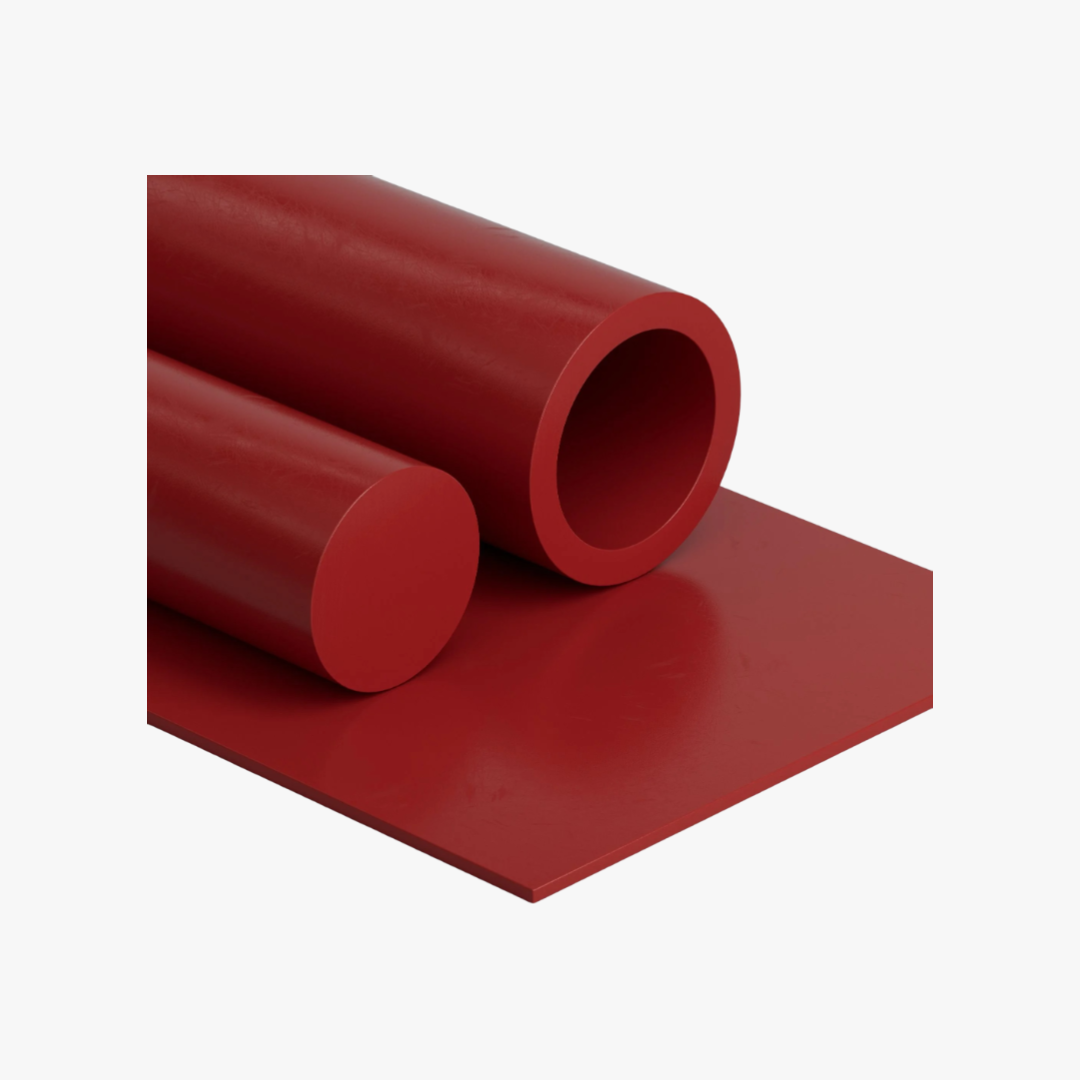

Nylon (PA)

₹100.00 Original price was: ₹100.00.₹90.00Current price is: ₹90.00.

Nylon PA is produced through two methods, cast and extrusion. Cast nylon demonstrates higher molecular weight, higher crystallization then extruded Nylon. Typically, Nylon is known for high mechanical strength, good wear resistance, sliding function and great machinability. In contrast to polyethylene products, Nylon absorbs moisture and is prone to expansion, as a result, it is not recommended for wet environments. Each grade of Nylon is manufactured to have different characteristics such as self lubrication, wax filled, UV – resistance and more. With our workshop in Sydney, B Plastics is able to machine components efficiently and with minimal tolerances.

Nylon Grades Available Include: Natural, Moly, Blue, Green, T-Glide, Aquanyl & Impact Resistant.

See Below For More Information.

For More Details About the Product Checkout the Pdf

Nylon (PA)

Applications

Applications Include:

- Crane Sheaves

- Carriage Wheels

- Outrigger Pads

- Heavy Load Bearings

- Gears & Sprockets

Standard Sizing

Rod (Natural, Moly, Blue, Green, T-Glide, Aquanyl & Impact Resistant) 1M Lengths:

Sheet (Natural, Moly, Blue, Green, T-Glide, Aquanyl & Impact Resistant) 2M X 1M:

RELATED PRODUCTS

Acetal (POM)

Acetal (POM-C) is a semi-crystalline thermoplastic with good dimensional stability and frictional properties. It contains high mechanical strength, toughness and provides an ease of machining not present in other plastics. Acetal is primarily for customers in which precision componentry with small tolerances are of importance. In contrast to Nylon, Acetal provides very low moisture absorption, making it a necessity for applications within a submerged or wet environment. This is due to its ability for mechanical properties to be maintained through wet or harsh environments. Chemically resistant, Acetal is also a great choice for corrosive conditions. With our workshop in Brisbane (QLD), B Plastic is able to machine components efficiently and with minimal tolerances.

PEEK (Polyetheretherketone)

PEEK material (polyetheretherketone) is a high-performance semi-crystalline engineering thermoplastic with outstanding harsh chemical resistance, very low moisture intake, good fire performance, excellent mechanical strength across a broad temperature range, and good dimensional stability. PEEK plastic is tough, strong, and rigid, with superior creep resistance, and is excellent for applications where thermal, chemical, and combustion properties are critical to performance. PEEK material retains its stiffness and strength for use in harsh high-pressure and high-temperature (HPHT) environments. PEEK is often used as the body for electrical connectors to minimize thermal expansion, provide chemical resistance, and to promote effective sealing. PEEK materials for a variety of sealing system components, as well as sensor housings and numerous high-performance applications in aircraft engines and other demanding environments. With our workshop in Brisbane (QLD), B Plastics is able to machine components efficiently and with minimal tolerances.

SAFEGUARD UV2™ Polycarbonate (PC)

Polycarbonate (PC) is a transparent, amorphous thermoplastic, offering excellent impact strength and high dimensional stability. A premium grade of plastic, polycarbonate has a high resistance to corrosive environments, excellent electrical stability and impact resistance. Outdoor applications are a particularly strong application for PC due to being lightweight and possessing great UV resistance. With our workshop in Brisbane (QLD), B Plastic is able to machine components efficiently and with minimal tolerances.

Sheet, Rod & Tube

Polyurethane is a versatile polymer renowned for its durability, flexibility, and resistance to abrasion, making it a sought-after material across various industries. B Plastics, a leading supplier in polymer solutions, offers a comprehensive range of sheet, rod, and tube in a variety of sizes. These polyurethane stock shapes cater to diverse applications, from engineering to manufacturing, providing superior performance and reliability in select applications. With B Plastics commitment to quality and precision, customers can trust in the consistency and integrity of their polyurethane material, ensuring optimal results for their projects.

Teflon (PTFE)

The properties of PTFE (Polytetrafluoroethylene) derive from its chemical structure, consisting of a bond of carbon and fluorine. PTFE is also known as an almost universal chemical resistance. The low co-efficient of friction as well as minimal abrasion wear create an excellent material for sliding applications. Additionally, PTFE will operate consistently within harsh UV and extreme heat environments, including temperatures up to 260°C. PTFE also has excellent electrical properties, allowing use within high voltage applications. PTFE is a physiologically inert material. Physiologically Inert materials are too dense to absorb bacteria or liquid, preventing it from expanding or contracting. As a result, PTFE is excellent for applications within the food or beverage industry.

With our workshop in Brisbane (QLD), B Plastic is able to machine components efficiently and with minimal tolerances.