Construction Applications

₹100.00 Original price was: ₹100.00.₹90.00Current price is: ₹90.00.

B Plastics offers a wide variety of thermoplastic and engineering products designed for the construction industry. Our services include supplying construction divinding boards, temporary fencing and partitioning walls, form and functional plastics, with materials such as HDPE ( High Density Polyethylene), UHMWPE, Poly Acetal, and (Polyamide) Nylon.

We are specialists in the reverse engineering of OEM components and sourcing engineering equipment. If you require specific parts or products that aren’t listed on our website, feel free to contact us, and we’ll be happy to assist. Our specialized nylon rope sheaves, for example, provide superior performance compared to steel due to their extended lifespan.

For enhanced safety, we also produce BigFoot Outrigger Pads, designed to offer secure and stable support for various lifting equipment. These pads help prevent accidents and injuries caused by unstable surfaces, inappropriate crane mats, or the lack of outrigger pads, ensuring safe operation of cranes and heavy machinery.

Engineering Plastics

The deciding factors for choosing engineering plastics are heavily dependent on its application. The following needs to be taken into consideration:

- Density (Weight)

- Corrosion Resistance

- Impact Resistance

- Is it Physiologically Inert?

- Sliding Abrasion Resistance

- Co-Efficient of Friction

- Temperature Resistance

- Dielectric Strength

- Weather Resistance

- Affordability

For the application of construction, common plastics include HDPE, UHMWPE, Acetal, Nylon and Polyurethane. This is mainly due to the requirement for either affordability or impact strength.

Nylon Rope Sheaves

b plastics specialises in the machining of Nylon rope sheaves. Capable of producing sheaves with a diameter of up to 600mm, 4th axis machining has drastically improved b plastics capabilities and production time. Benefits of Nylon sheaves as opposed to steel include:

Conveyor Accessories include:

- Longer estimated rope life.

- Extended Sheave lifespan (approximately 3 times)

- Corrosion Resistant

- Lower weight

Bigfoot Outrigger Pads

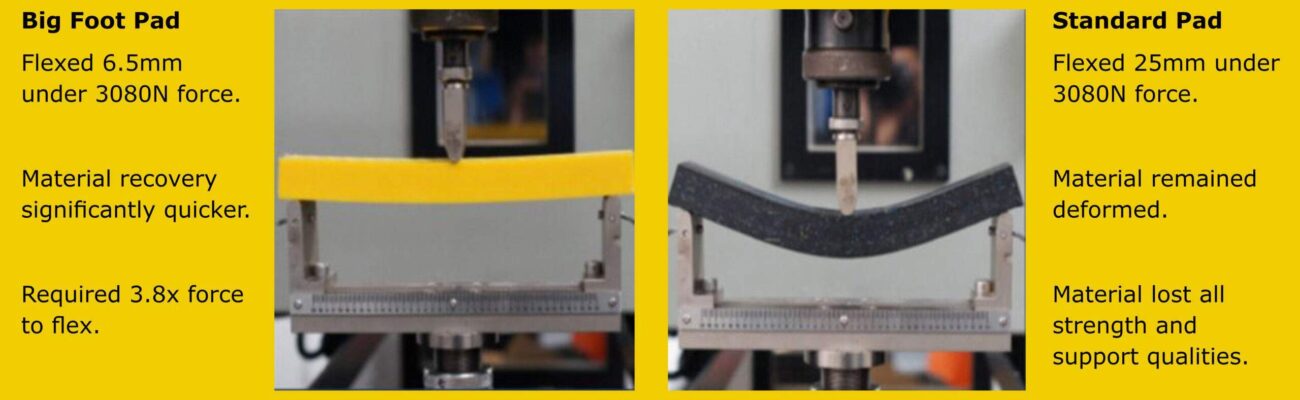

No compromises should be made with respect to the safety of a construction or mining site. 75% of all crane stability issues stem from inadequate or improper operation of outriggers. Site proven over the last 15 years, Big Foot Outrigger pads are manufactured with premium cast Nylon. To demonstrate the superior strength of the Big Foot Pads, a comparison is shown below with standard PE Crane Pads:

Typically Applicable Equipment:

Standard Sizing:

Round

| O/D (mm) | O/D (inches) | Thickness (mm) | Thickness (inches) | Weight (KG) | Weight (lbs) | Number of Rope Handles |

|---|---|---|---|---|---|---|

| 300 | 11.81 | 40 | 1.57 | 3.22 | 7 | 1 |

| 500 | 19.68 | 40 | 1.57 | 9 | 19.84 | 2 |

| 600 | 23.62 | 40 | 1.57 | 13 | 28.66 | 2 |

| 750 | 29.52 | 40 | 1.57 | 20 | 44.09 | 2 |

| 900 | 35.43 | 40 | 1.57 | 29 | 63.93 | 2 |

| 1000 | 39.37 | 40 | 1.57 | 36 | 79.36 | 2 |

| 1000 | 39.37 | 50 | 1.96 | 49 | 108 | 2 |

| 1220 | 48.03 | 50 | 1.96 | 66 | 145.5 | 2 |

Square

| O/D (mm) | O/D (inches) | Thickness (mm) | Thickness (inches) | Weight (KG) | Weight (lbs) | Number of Rope Handles |

|---|---|---|---|---|---|---|

| 300 | 11.81 | 40 | 1.57 | 4 | 8.81 | 1 |

| 500 | 15.74 | 40 | 1.57 | 11.5 | 25.35 | 2 |

| 600 | 23.62 | 40 | 1.57 | 16.5 | 36.37 | 2 |

| 750 | 29.52 | 40 | 1.57 | 26 | 57.32 | 2 |

| 900 | 35.43 | 40 | 1.57 | 37 | 81.57 | 2 |

| 1000 | 39.37 | 40 | 1.57 | 46 | 101.41 | 2 |

| 1000 | 39.37 | 50 | 1.96 | 62 | 136.68 | 2 |

| 1220 | 48.03 | 50 | 1.96 | 93 | 205.03 | 2 |