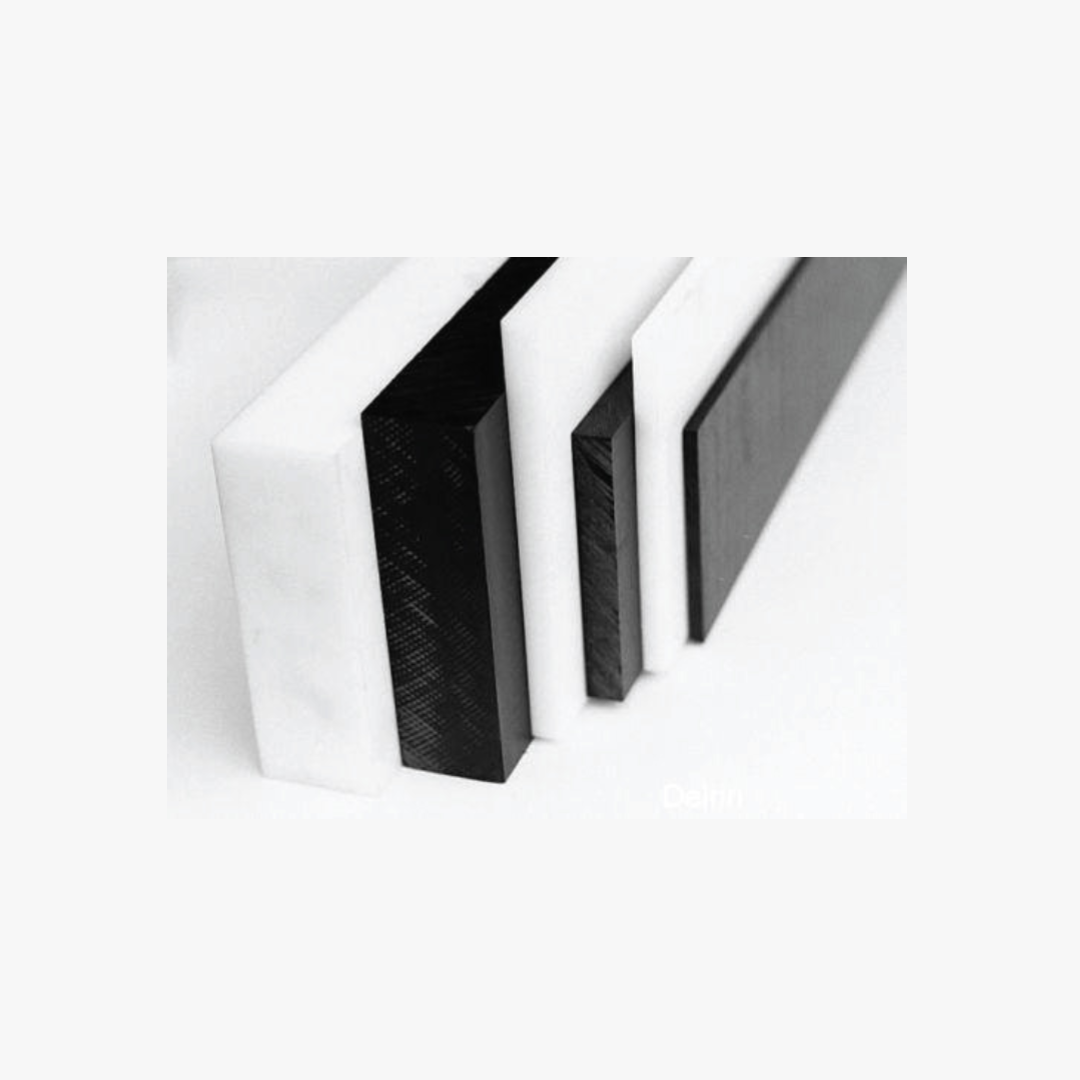

Ultra High Molecular Weight Polyethylene (UHMWPE)

₹100.00 Original price was: ₹100.00.₹90.00Current price is: ₹90.00.

Ultra high molecular weight polyethylene is a thermoplastic engineering plastic. Ultra high molecular weight polyethylene is a material with a molecular weight of 105 million in PE, and UHMW-PE has excellent properties. It combines all the advantages of plastic, such as high wear resistance, high impact strength, self-lubricating, corrosion-resistant, shock-absorbing, low temperature resistance, non-toxic, anti stick, low water absorption and other outstanding features. UHMWPE is the most excellent high-performance engineering plastic.

While it can be fabricated and machined, it may not form specific shapes as easily as HDPE. Nonetheless, it performs exceptionally well in resisting friction and wear over time. UHMWPE is FDAcompliant making it suitable for food-related applications.

We have more than 20 years of experience to machine UHMWPE components to minimal tolerances, ensuring precise and high-quality outcomes.

For More Details About the Product Checkout the Pdf

Ultra High Molecular Weight Polyethylene (UHMWPE)

Applications

Applications Include:

- Conveyor Rollers

- Timing Screws

- Skating Surfaces

- Wear Pad Liners

- Wear Profiles for Conveyor Lines