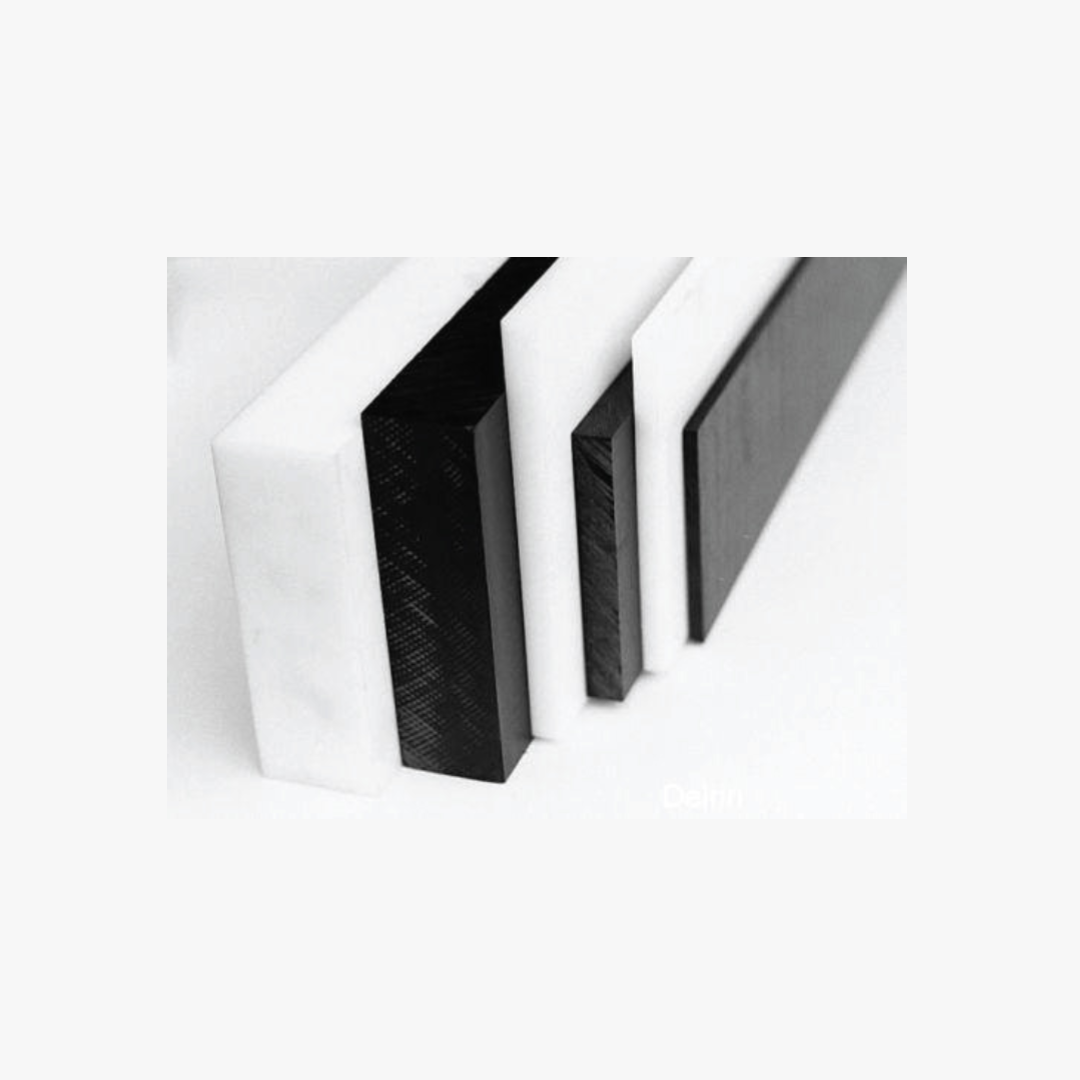

Ultra High Molecular Weight Polyethylene (UHMWPE)

₹100.00 Original price was: ₹100.00.₹90.00Current price is: ₹90.00.

In the same polyethylene family as HDPE, Ultra-High Molecular Weight Polyethylene (UHMWPE) is dense, strong and abrasion-resistant. It’s especially well suited for holding up against wear from constant friction between moving parts. UHMWPE is fairly low cost and can be used for a wide variety of applications. Though it can be fabricated and machined, it’s not as well suited to forming specific shapes as HDPE. However, it is generally able to hold up better against friction and wear over time. Relevant for food related applications, UHMWPE is compliant with FDA/BfA requirements and is physiologically inert.

With our workshop in Sydney, B Plastic is able to machine components efficiently and with minimal tolerances.

For More Details About the Product Checkout the Pdf

Ultra High Molecular Weight Polyethylene (UHMWPE)

Applications

Applications Include:

- Liners

- Wear Profiles

- Conveyor Components & Rollers

- Scrolls

- Skating Rink Surfaces

Standard Sizing

Rod (Natural, Black & Green) 1M/3M Lengths:

Sheet (Natural, Black, Blue & Green) 3MX1.25M & 2MX1M:

RELATED PRODUCTS

HDPE (High Density Polyethylene)

PEEK (Polyetheretherketone)

PEEK material (polyetheretherketone) is a high-performance semi-crystalline engineering thermoplastic with outstanding harsh chemical resistance, very low moisture intake, good fire performance, excellent mechanical strength across a broad temperature range, and good dimensional stability. PEEK plastic is tough, strong, and rigid, with superior creep resistance, and is excellent for applications where thermal, chemical, and combustion properties are critical to performance. PEEK material retains its stiffness and strength for use in harsh high-pressure and high-temperature (HPHT) environments. PEEK is often used as the body for electrical connectors to minimize thermal expansion, provide chemical resistance, and to promote effective sealing. PEEK materials for a variety of sealing system components, as well as sensor housings and numerous high-performance applications in aircraft engines and other demanding environments. With our workshop in Brisbane (QLD), B Plastics is able to machine components efficiently and with minimal tolerances.

Polyester (PET)

Sheet, Rod & Tube

Polyurethane is a versatile polymer renowned for its durability, flexibility, and resistance to abrasion, making it a sought-after material across various industries. B Plastics, a leading supplier in polymer solutions, offers a comprehensive range of sheet, rod, and tube in a variety of sizes. These polyurethane stock shapes cater to diverse applications, from engineering to manufacturing, providing superior performance and reliability in select applications. With B Plastics commitment to quality and precision, customers can trust in the consistency and integrity of their polyurethane material, ensuring optimal results for their projects.

Teflon (PTFE)

The properties of PTFE (Polytetrafluoroethylene) derive from its chemical structure, consisting of a bond of carbon and fluorine. PTFE is also known as an almost universal chemical resistance. The low co-efficient of friction as well as minimal abrasion wear create an excellent material for sliding applications. Additionally, PTFE will operate consistently within harsh UV and extreme heat environments, including temperatures up to 260°C. PTFE also has excellent electrical properties, allowing use within high voltage applications. PTFE is a physiologically inert material. Physiologically Inert materials are too dense to absorb bacteria or liquid, preventing it from expanding or contracting. As a result, PTFE is excellent for applications within the food or beverage industry.

With our workshop in Brisbane (QLD), B Plastic is able to machine components efficiently and with minimal tolerances.